Drive-In Racking

Fast response, expert help.

Prefer to talk to someone?

Drive-In/Drive-Thru Racking

Intuitive User Interface

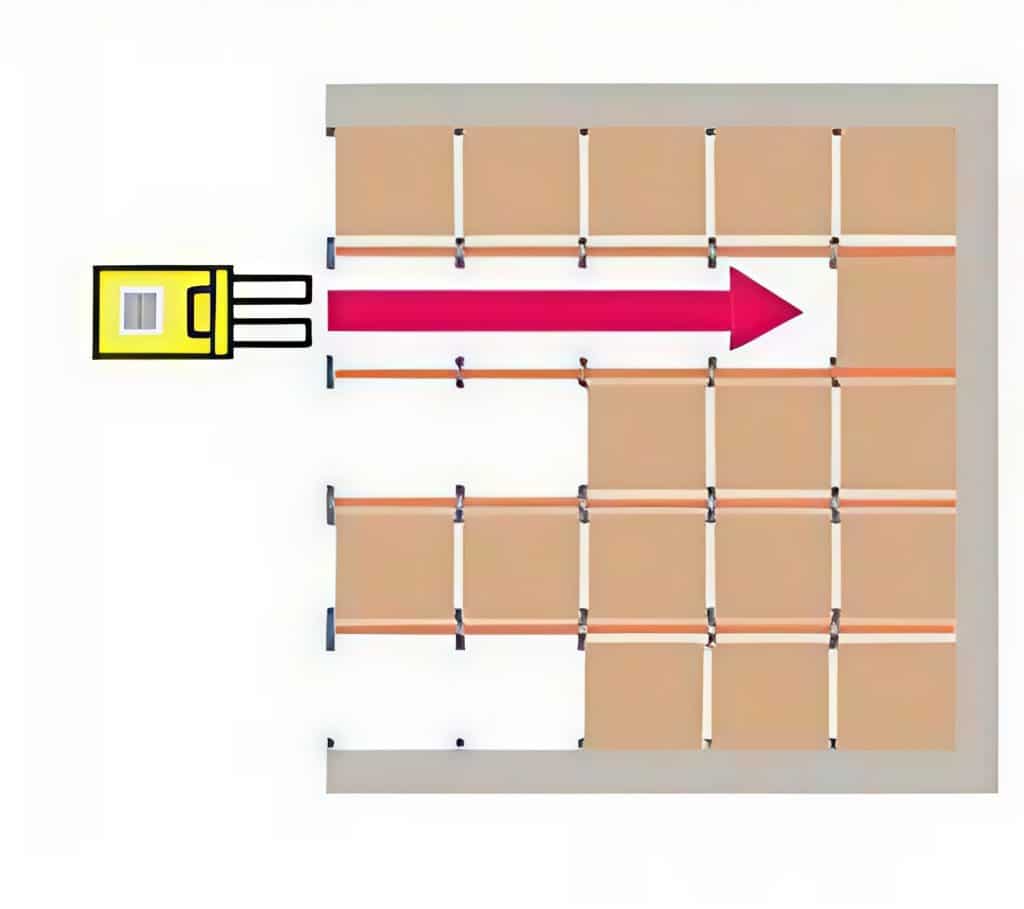

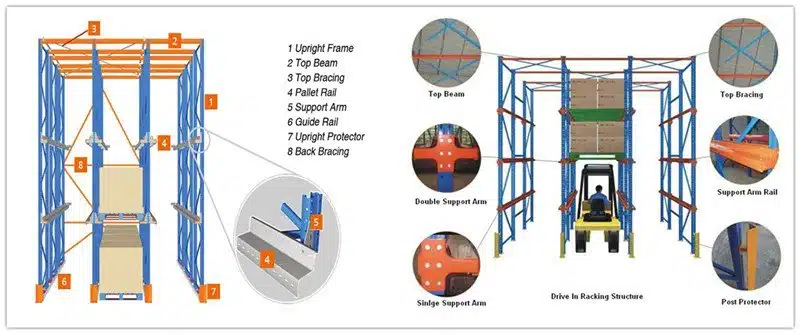

Drive-in racking is a high-density storage system designed to maximize pallet capacity by reducing aisle space. Ideal for bulk storage, it uses a Last-In, First-Out (LIFO) system, making it perfect for products with longer shelf lives or uniform SKUs.

Key Benefits:

•Space Efficiency: Reduces aisle space by up to 90%, allowing you to store more in less square footage.

•Cost-Effective Storage: Ideal for cold storage and bulk inventory, helping you optimize your warehouse footprint.

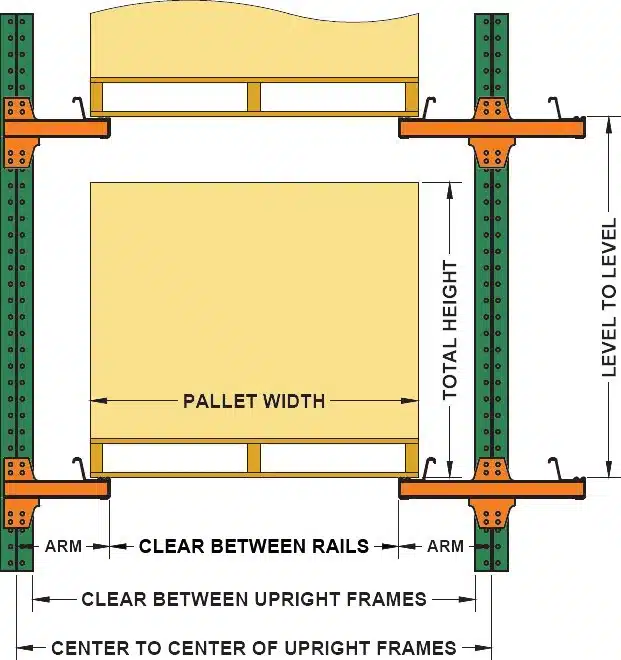

•Durable & Customizable: Built with heavy-duty steel and tailored to fit your pallet sizes and layout needs.

Why Drive Thru Racking?

In a temperature-controlled cold storage facility where every square foot counts, Drive-In Racking offers the high-density storage needed to maximize capacity while keeping energy costs low. This warehouse handles large volumes of a single frozen product per chamber such as meat, seafood, or packaged produce making drive-in racking the ideal solution for storing multiple pallets of the same SKU in deep, compact lanes. Forklifts drive directly into the racking structure to load and retrieve pallets, minimizing aisle space and dramatically increasing pallet positions per cubic foot.

| PROS | CONS |

|---|---|

| Maximizes pallet positions by minimizing aisle space | Limited selectivity harder to access individual pallets |

| Ideal for high-density, low-SKU storage | LIFO design not ideal for FIFO inventory systems |

| Excellent for storing large volumes of the same product | Requires skilled forklift operators to avoid rack damage |

| LIFO (Last-In, First-Out) system works well for non-perishable items | Lower speed of operation compared to selective racking |

| Excellent for storing large volumes of the same product | Much higher upfront investment compared to pallet racks. |