Push-Back Racking

Fast response, expert help.

Prefer to talk to someone?

Push Back-Racking

What is push-back racking?

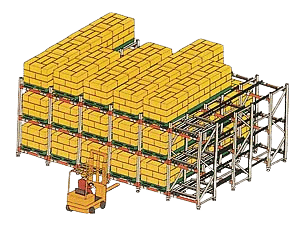

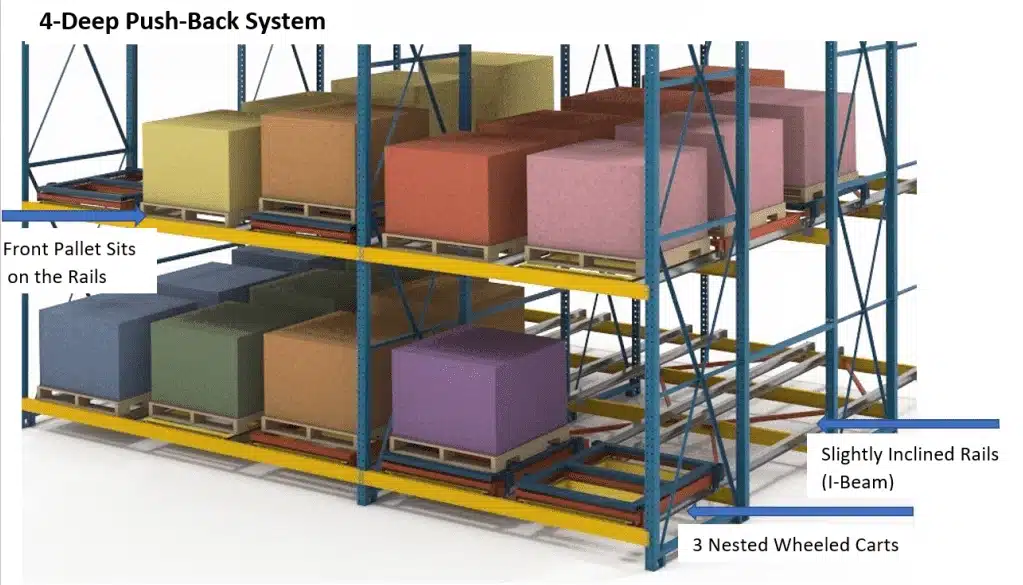

Push back racking is a space-saving storage solution that uses nested carts on inclined rails, allowing you to store multiple pallets deep while maintaining quick access. Perfect for high-volume, low-turnover products, it operates on a Last-In, First-Out (LIFO) system, making it ideal for bulk storage.

Key Benefits:

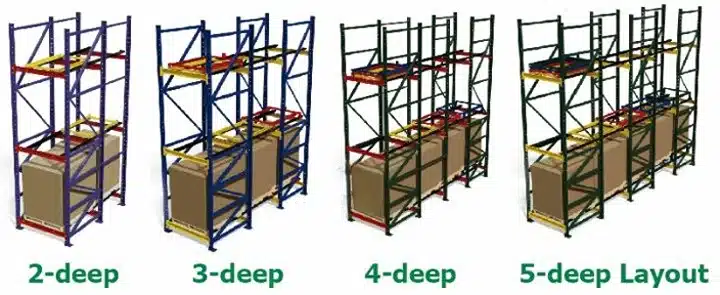

•Maximizes Storage Density: Store 2 to 6 pallets deep per lane, reducing aisle space.

•Efficient Loading & Retrieval: Pallets slide forward automatically for faster access.

•Durable & Reliable: Built with heavy-duty steel to handle large, heavy loads.

•Perfect for Bulk Storage: Ideal for cold storage, manufacturing, and distribution centers.

| PROS | CONS |

|---|---|

| Increases storage density by reducing aisle space | Works on a Last-In, First-Out (LIFO) system |

| Increases storage density by reducing aisle space | Not ideal for all SKUs – best for bulk storage |

| Reduces travel time with fewer aisles to navigate | Higher upfront cost compared to selective racking |

| Great for medium-turnover inventory | Limited visibility of pallets stored deeper |