How Warehouse Layout Design Saves Money and Space in Southern California Warehouses

Warehouse space in Southern California is expensive, competitive, and increasingly hard to find. From Los Angeles and Orange County to the Inland Empire, warehouses are under pressure to store more product, move it faster, and do it all without expanding their footprint. For many operators, the difference between an efficient operation and a costly one comes down to a single factor — warehouse layout design.

A well-planned warehouse layout does more than organize pallet racking. It directly reduces operating costs, increases usable space, improves forklift flow, and prevents expensive rework later. In Southern California, where real estate and labor costs continue to rise, layout design is one of the smartest investments a warehouse can make.

Need help designing your warehouse with racking?

Warehouse Layout Design for Pallet Racking in Southern California Warehouses

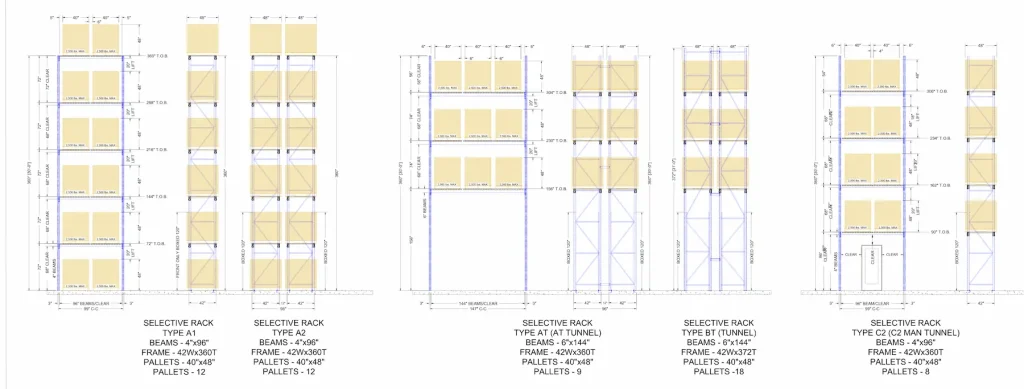

Pallet racking takes up the majority of space in most warehouses, which makes layout design critical. Poorly planned layouts often waste vertical space, create oversized aisles, or leave unusable floor areas that don’t contribute to storage capacity.

Warehouse layout design focused on pallet racking helps Southern California warehouses:

- Maximize pallet positions without increasing square footage

- Use building height efficiently

- Match aisle widths to actual forklift requirements

- Eliminate dead space along walls and columns

- Balance density with accessibility

In high-demand areas like Ontario, Fontana, Chino, and Riverside, even small layout improvements can translate into hundreds of additional pallet positions. That added capacity directly reduces the need for overflow storage, off-site warehousing, or early facility expansion.

When pallet racking is designed around the building not forced into it space efficiency improves immediately.

How Warehouse Layout Design Reduces Operating Costs in Southern California Warehouses

Labor is one of the largest expenses for Southern California warehouses. Poor layouts increase travel time, create congestion, and slow down picking, receiving, and shipping. Over time, those inefficiencies add up to significant cost.

Strategic warehouse layout design reduces operating costs by:

- Shortening forklift travel paths

- Improving traffic flow between receiving, storage, and shipping

- Reducing congestion at high-traffic aisles

- Separating pedestrian and forklift zones

- Creating logical pick and replenish paths

In fast-paced Inland Empire distribution centers and LA-area fulfillment warehouses, every extra forklift move costs time and money. A cleaner, more efficient layout reduces wasted motion and allows the same workforce to move more product each shift.

That efficiency becomes even more valuable during peak seasons when volume increases but labor availability stays tight.

Saving Money by Avoiding Costly Racking Changes and Rework

One of the most expensive mistakes Southern California warehouses make is installing pallet racking before the layout is properly planned. When growth happens or operations change, warehouses are forced to relocate aisles, remove racks, or redesign entire sections — all of which costs time and money.

Warehouse layout design helps avoid these problems by:

- Planning for future expansion from day one

- Accounting for different rack types and storage needs

- Anticipating SKU growth and product changes

- Designing flexible layouts that can be reconfigured

- Reducing the likelihood of reinstallation or demolition

For warehouses in Orange County and Los Angeles operating in older buildings, this foresight is especially important. Layout design ensures pallet racking fits the building’s constraints while still allowing room to grow.

Spending time on layout design upfront often saves tens of thousands of dollars later.

Using Warehouse Layout Design to Improve Safety and Reduce Damage in SoCal Warehouses

Safety issues are costly not just financially, but operationally. Forklift damage, rack impacts, blocked aisles, and poor traffic flow increase the risk of accidents and downtime. In Southern California warehouses with heavy daily traffic, safety and efficiency are closely connected.

Warehouse layout design improves safety by:

- Aligning aisles with forklift turning radiuses

- Reducing blind spots and tight intersections

- Keeping emergency exits and fire lanes clear

- Maintaining required clearances and flue space

- Creating safer pedestrian walkways

Well-designed layouts also reduce damage to pallet racking. When aisles are too narrow or poorly positioned, forklifts are more likely to clip uprights and beams. Layout design minimizes these risks and helps protect the racking investment long-term.

For high-traffic facilities in Commerce, Vernon, and the Inland Empire, improved safety translates directly into lower repair costs and fewer interruptions.

Why Warehouse Layout Design Is Especially Important in Southern California

Southern California warehouses face unique challenges that make layout design even more valuable than in other regions:

- Higher real estate costs

- Taller racking due to limited square footage

- Higher forklift traffic volumes

- Faster-paced operations tied to port activity

- Strict fire and building code requirements

- Seismic considerations

Because of these factors, mistakes are more expensive and harder to fix. A layout that works in another state may not work in Southern California without adjustments for code, traffic, or building limitations.

Professional warehouse layout design ensures pallet racking is installed efficiently, compliantly, and with long-term performance in mind.

Planning on moving warehouses, leasing a new one or want to begin designing pallet racks from the ground up?