Why Column Protectors and End-of-Aisle Protectors Matter for Pallet Racking Safety in Southern California Warehouses

Southern California warehouses operate in fast-paced environments with constant forklift movement, tight aisles, and high pallet turnover. From heavy distribution hubs in the Inland Empire to fulfillment centers in Los Angeles and Orange County, one of the biggest ongoing risks is damage to pallet rack uprights. Even minor forklift contact can weaken the structure, create long-term safety concerns, and lead to expensive repairs.

That’s why column protectors and end-of-aisle protectors have become essential safety components in nearly every SoCal warehouse. They safeguard racking from impact, reduce downtime, and help facilities stay compliant with safety guidelines and inspection standards.

Here’s why warehouse operators across Southern California rely on these protective accessories to keep their pallet racking safe and operational.

Looking to Add Column Protectors or End of Aisle Protectors for your pallet racks?

How Column Protectors Protect Pallet Racking in Southern California Warehouses

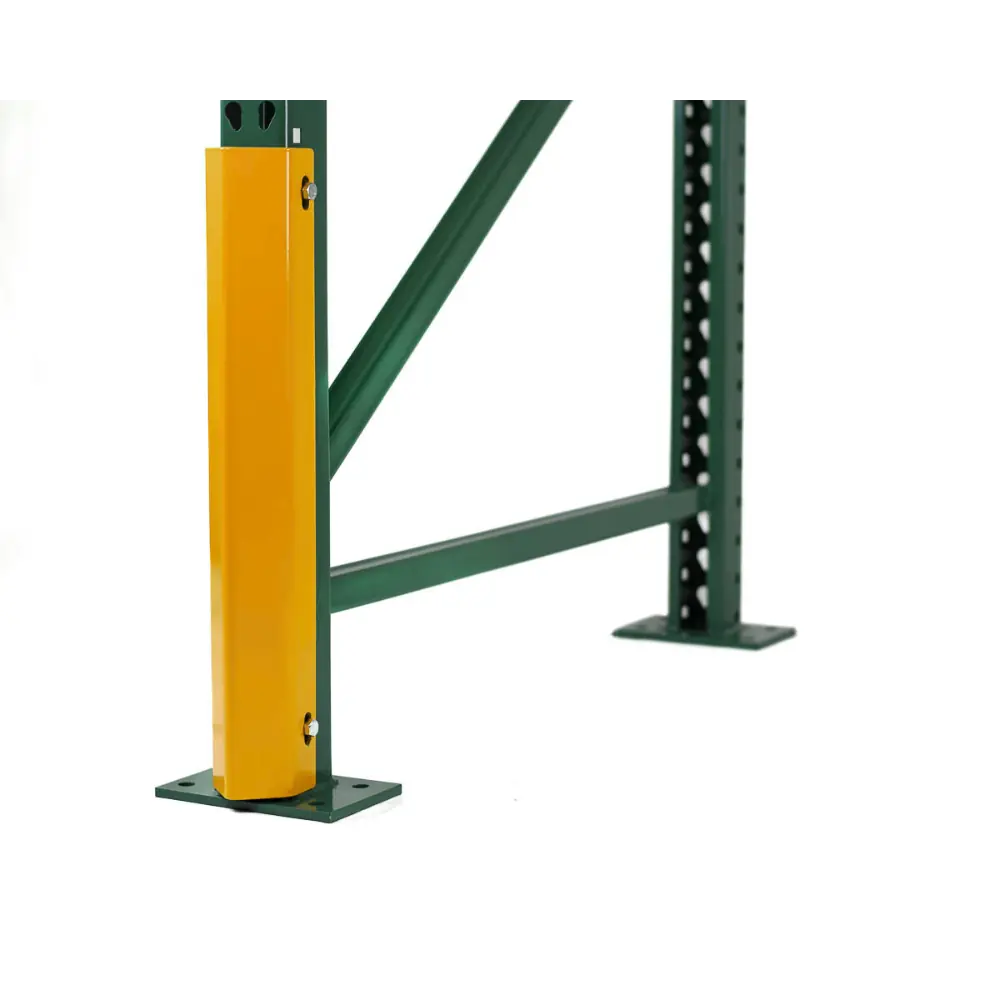

Column protectors (also called upright protectors) are engineered to shield the base of the pallet rack upright — the most vulnerable point in any racking layout. In Southern California warehouses, forklifts and reach trucks move quickly, often working in narrow aisles with little room for error. Even a light bump can bend an upright, reduce load capacity, or cause a dangerous lean.

Column protectors help prevent:

- Forklift impact damage

- Rack instability

- Upright bending or buckling

- Costly repairs or full upright replacements

Warehouses in Ontario, Fontana, Riverside, and Long Beach often run multiple shifts where operators are under pressure to move pallets quickly. Column protectors absorb accidental contact so the racking structure doesn’t take the hit.

Because pallet racking is engineered to specific capacities, protecting the uprights is critical. Once an upright is damaged, the entire bay or aisle can be compromised. Column protectors offer inexpensive insurance against this, making them one of the highest-ROI accessories in any warehouse.

Why End-of-Aisle Protectors Are Crucial for Pallet Racking Safety in Southern California

End-of-aisle protectors (also called end guards or rub rails) reinforce the most exposed areas of a racking layout — the ends of aisles where forklift traffic is highest. These areas experience the majority of impact incidents because operators make sharp turns, drive toward picking lanes, and transition from aisle to aisle.

Southern California warehouses with high-frequency movement rely heavily on these protectors because they:

- Shield the first uprights on each aisle

- Reduce side impacts from turning forklifts

- Maintain aisle alignment over time

- Prevent structural weakening in high-traffic zones

LA County warehouses, e-commerce facilities, and 3PLs in the Inland Empire often prefer heavy-duty steel aisle guards because they endure constant traffic without deforming.

The ends of aisles are the gateway to every pallet position, making these protectors essential for keeping the layout safe and extending the lifespan of pallet racking.

Why Southern California Warehouses Need Rack Protection for Safety, Compliance, and Inspections

California warehouses undergo frequent safety audits, insurance inspections, and internal compliance checks. Damaged pallet rack uprights are one of the most common violations and one of the fastest ways to fail an inspection.

Column protectors and end-of-aisle protectors help warehouses:

- Stay OSHA compliant

- Reduce rack repair frequency

- Prevent shutdowns due to unsafe racking

- Maintain consistent load capacities

- Protect employees working near racking

Fire marshals and third-party inspectors in SoCal pay close attention to structural integrity. A bent upright or compromised frame can result in required repairs, citations, or inventory relocation. Protecting racking from the start prevents these operational disruptions.

With high storage densities and busy forklift lanes common throughout Southern California, proactive rack protection is not a luxury — it’s a necessity.

How Column Protectors and End-of-Aisle Guards Reduce Costs for SoCal Pallet Racking Operations

Repairing damaged pallet racking is expensive. Upright replacements require unloading entire bays, removing beams, scheduling installers, and coordinating downtime. In busy warehouses, that downtime turns into real financial loss.

Column protectors and end-of-aisle guards help Southern California warehouses:

- Avoid full upright replacements

- Reduce beam removal and reinstallation labor

- Lower long-term maintenance costs

- Minimize operational downtime

- Prevent damage from turning forks or misaligned pallets

Because many SoCal facilities operate nearly 24/7 — especially those tied to ports or ecommerce — downtime is extremely costly. Rack protection prevents these bottlenecks and keeps operations moving smoothly.

For high-volume locations in Chino, Commerce, Vernon, or San Bernardino, these protectors pay for themselves within the first few avoided incidents.

Why Rack Protection Matters More in Southern California Warehouses Compared to Other Regions

Southern California warehousing combines several unique factors:

- Higher forklift traffic due to fast-moving operations

- Narrower aisles in older LA and OC buildings

- Higher employee turnover and varied forklift operator skill levels

- Pressure to move pallets quickly due to port-driven demand

- Strict safety and fire regulations

- Higher seismic activity

All of these amplify the need for column protectors and end-of-aisle guards.

Seismic stability is especially important. A weakened upright in a high-seismic zone poses a much greater structural risk. Protecting racking reduces the chances of a compromised frame becoming a hazard during movement or seismic activity.

This is why nearly every modern warehouse layout in Southern California includes these protectors by default.

Need a quote for Column Protectors or End of Aisle Protectors?