Drive-In Racking for High-Density Storage in California Warehouses

In California’s tight warehouse market, drive-in racking systems are becoming a go-to solution for businesses that need to maximize storage capacity without expanding their footprint.

If your operation stores large quantities of the same product, a drive-in system can dramatically increase density while keeping costs low. Schedule a free warehouse layout review to see how IMH can design and install a system that fits your exact space and workflow.

What Is Drive-In Racking?

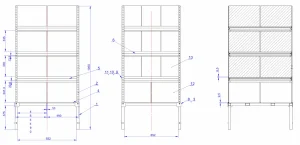

Drive-in racking is a high-density storage system where forklifts drive directly into storage lanes to place or retrieve pallets. Instead of multiple aisles, pallets are stored several positions deep, supported by continuous rails on both sides.

Each lane is dedicated to a single SKU, making this system ideal for bulk storage and last-in, first-out (LIFO) inventory rotation. Many California food distributors, cold storage facilities, and manufacturing plants rely on drive-in systems to store thousands of pallets efficiently.

Benefits for California Warehouses

With rising warehouse rents in major logistics hubs like Ontario, Fontana, and Riverside, every square foot counts. Drive-in racks can increase usable storage volume by up to 75% compared to standard selective racks.

Key advantages include:

- Maximum pallet density: Reduce the number of aisles and store more product in the same footprint.

- Lower construction costs: No need to expand your facility or lease more space.

- Ideal for cold storage: Minimizes air volume, reducing refrigeration costs.

- Durable design: Heavy-gauge uprights and rail supports withstand repeated forklift entry.

- Custom configurations: Tailored rail heights, entry guides, and clearances for your equipment and pallet size.

For operations that handle limited SKUs or high-volume seasonal products, drive-in systems provide an unmatched return on investment.

IMH Drive-In Racking Manufacturing and Installation

At IMH, we design and manufacture drive-in pallet racking systems engineered for your exact pallet size, load weight, and forklift type.

Each project begins with on-site measurements, followed by a custom CAD layout that accounts for dock doors, fire lanes, and traffic flow.

Our bonded installers handle full installation from anchoring and bracing to seismic and fire-code compliance. Based in Riverside, CA, we service warehouses across the Inland Empire and Southern California, ensuring fast turnaround and responsive support.

Learn more about our Custom Rack Manufacturing services to see how we can tailor every upright, rail, and beam to your needs.

Why Choose IMH for Drive-In Racking

Our experience covers industries from cold storage and 3PL logistics to CPG and food distribution, giving us the insight to design drive-in systems that balance efficiency and compliance.

We also understand the local permitting process. Every layout we design considers fire tunnel spacing, egress clearance, and seismic stability ensuring you stay code-ready whether your warehouse is in Ontario, Fontana, or Los Angeles County.

IMH isn’t just a racking supplier we’re your warehouse design partner. Our layouts focus on flow, forklift access, and long-term scalability, so your investment performs for years.