What can I use instead of Pallet Racks?

When Pallet Racking Isn’t the Right Fit

Pallet racking is the gold standard for warehouse storage. It’s scalable, strong, and compatible with nearly every type of operation. But there are times when it’s just not the right choice maybe due to budget, space, product type, or even temporary needs.

So what can you use instead of pallet racking?

Let’s break down the most common alternatives from professional-grade solutions to temporary options—and when you should (and shouldn’t) use them.

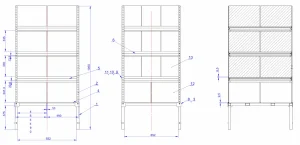

1. Boltless Shelving (Best for hand-loaded items)

Boltless shelving is a lightweight, hand-loaded solution—ideal for smaller inventory, pick-and-pack operations, or backrooms. It’s great when forklifts aren’t in the mix.

- Hand picking

- Inventory rooms

- Ecommerce fulfillment

- Light-duty parts or cartons

Pros:

Doesn’t require forklifts

Easy to assemble and adjust

Cost-effective

2. Cantilever Racking (Ideal for long or awkward materials)

If you’re storing materials like pipe, lumber, or furniture, cantilever racks are far more effective than standard pallet racks.

Pros:

Great for bulky, irregular items

Open-front design for easy loading

Adjustable arms for different lengths

Why it works:

Supports heavy-duty loads

Open front design = easy loading

Arms adjust to different lengths

3. Floor Stacking or Double Stacking Pallets

Floor stacking is when you simply stack pallets directly on the warehouse floor, without any racking. Some operations double-stack pallets to save vertical space.

Why some warehouses use it:

- No equipment needed

- Very low cost

- Works for temporary or overflow inventory

But here’s the catch:

- Poor space efficiency

- Higher damage risk

- No vertical utilization

- Major safety and accessibility concerns

👉 While it might save money upfront, floor stacking is a short-term bandage not a sustainable solution for modern operations. When you’re ready to optimize, we’ll help you build a plan that scales.

4. Carton Flow Racking (Great for fast-moving SKUs)

Carton flow uses a gravity-fed design to push boxes forward as others are picked, which improves speed and picking accuracy in high-volume environments.

Pros:

Reduces walking time for pickers

First-in, first-out (FIFO) friendly

Great for ecommerce and consumer goods

🧠 Not Sure What System Fits Your Space?

We’ve helped businesses across the U.S. optimize their warehouse layouts with the right mix of racking, shelving, and storage systems. Whether you’re moving into a new facility or reworking an existing one, we’ll design a layout that maximizes space and minimizes headaches.

Contact Us Today!